Technologies

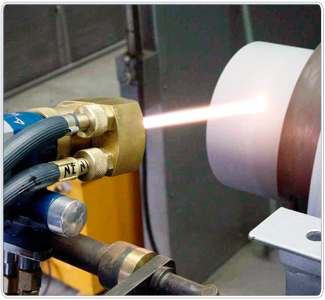

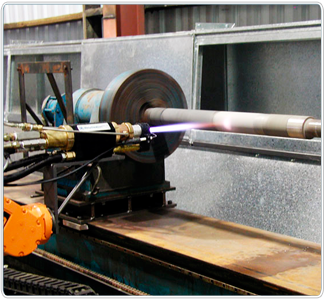

Thermal spray uses kinetic and thermal energy and is based on the continuous impact of a fluid, molten or semi-molten material, to grow a coating on a surface.

Two main families of thermal spray

Greatest difference among different thermal spray processing relies on the energy source used to heat the material and hence flight characteristics of the particles.

In high velocity processes were a mixture of fuel, whether gas or liquid such as propane, hydrogen, propylene, kerosene, ethanol, etc., and an oxidant gas to generate a constant ignition reaction within a combustion chamber. Exhaustion gases from combustion reaction along with powder particles travel through the nozzle until it impacts the substrates surface which is to be coated.

Combustion thermal spray is also known as high velocity combustion processes as:

- High velocity oxy-fuel thermal spray (HVOF).

- High velocity air-fuel spray (HVAF).

- High velocity oxy-liquid fuel thermal spray (HVOLF).

This techniques have acquired great interest of study due to the fact that they produce dense homogeneous coatings with good adherence, low porosity, and low oxide contents by means of the range of working temperature.